3d Printer Tool Changer

I have been the proud owner of a self build 3D-printer for quite a while. And while when it is completely assembled it works fine, I have been itching to upgrade it to use multiple tools. My final goal with this printer is to print in four different colors/materials, and print this impressive catan set. I have looked at some other options for multi-material-printing, namely a multi nozzle hotend, and a 2 in 1 mixing hotend. The second option works fine for 2 materials, if a bit finicky. But is not something I want to expand to 4. Thus I decided to look into hotend switching.

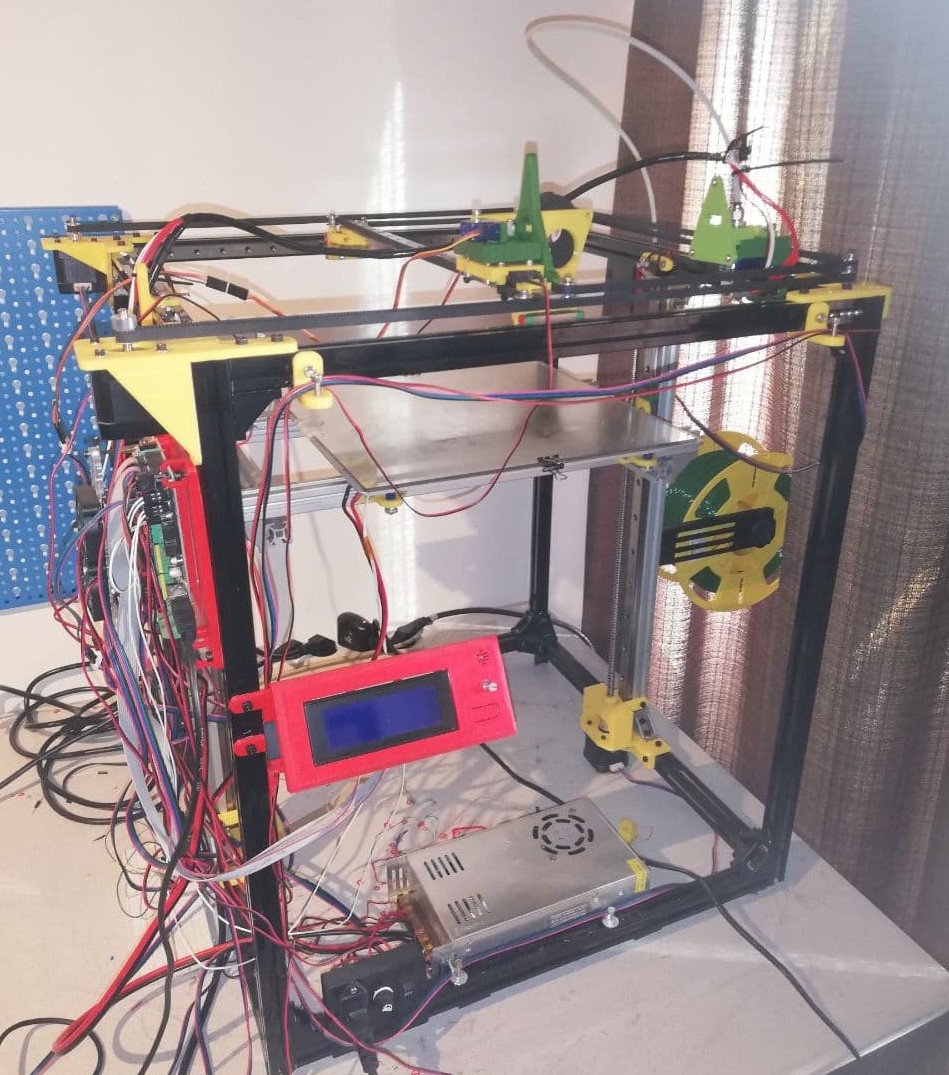

First, let me show you my printer. This printer, usually called “Cube” in my config files, is a CoreXY printer based on linear rails.

The motherboard is a MKS gen L and it has dual lead screws for the Z axis. The printing area is 300x300x450, mainly due to me not having a larger bed.

As you can see in its picture, it is a bit of a mess of wires.

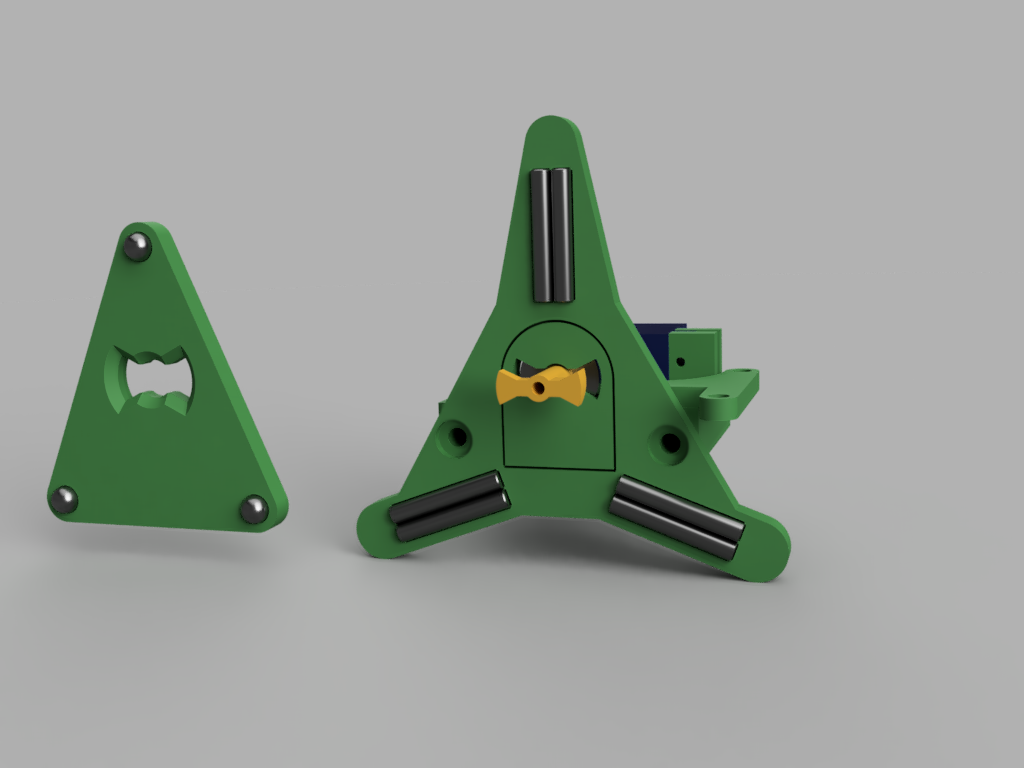

On the top right you can see my current attempt at a tool changer. This tool changer uses three 6mm ball bearings, and 6 4mm rods to create a kinematic coupling.